The precision and efficiency of the wide belt sander have replaced the traditional manual sanding. According to various factors of different wood sanding processes, it is suitable for the process flexibility of different workpieces and has a high adaptability to the thickness tolerance of workpieces, ensuring high processing accuracy and stable processing quality.

| Model | RM130R-RP | RM60R-RP |

|---|---|---|

| Max. Working width | 20-1300mm | 20-600mm |

| Thickness of sanded panel | 3-100mm | 3-100mm |

| Feed speed | 3-20m/min | 3-20m/min |

| Diameter of 1st roller | Φ240mm | Φ190mm |

| Diameter of 2nd roller | Φ210mm | Φ140mm |

| Power of abrasive belt on 1st unit | 30Kw | 11kw |

| Power of abrasive belt on 2nd unit | 22Kw | 7.5kw |

| Conveyer motor power | 4Kw | 1.5kw |

Wide belt sander is an efficient equipment used for surface treatment of various wood panels in woodworking machinery. Its working principle is to tightly wrap sandpaper around the contact roller, and then use it to perform fine sanding treatment on the wood panels.

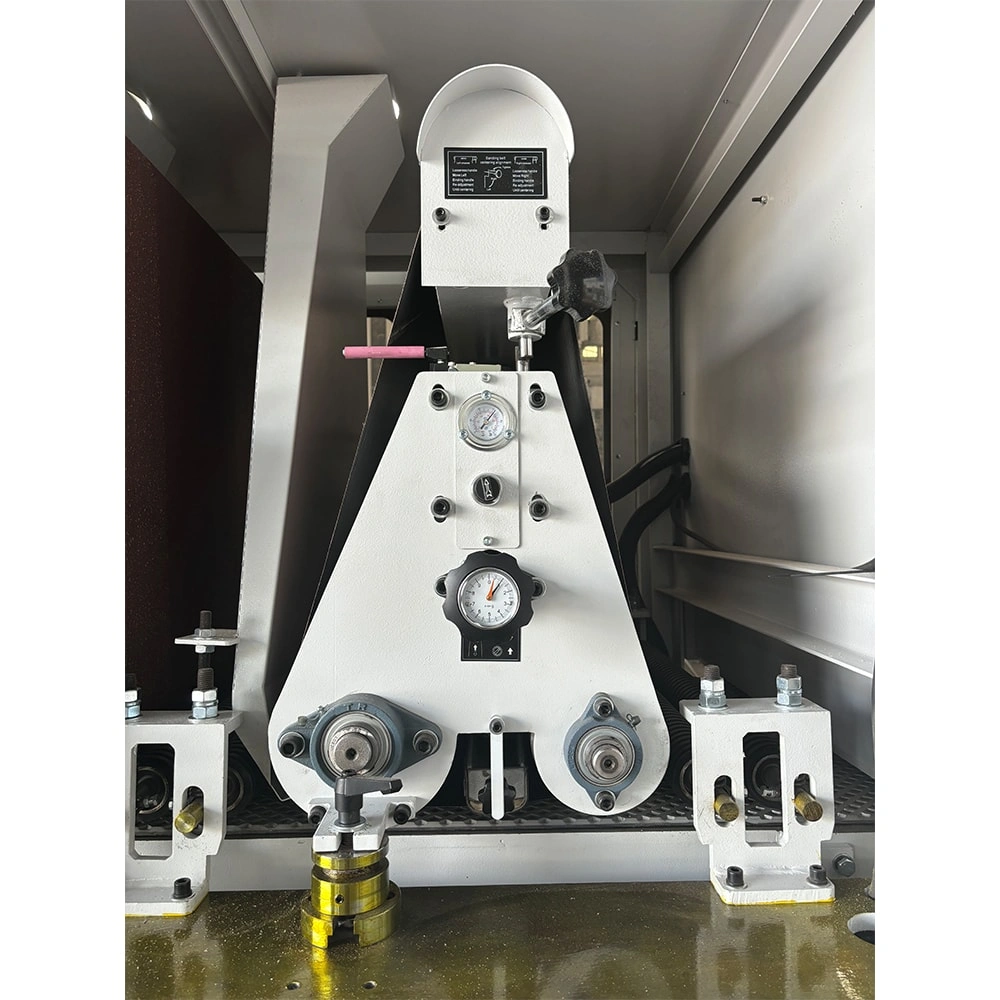

There are many combinations of rollers for wide belt sander ,R-RP is the most common combination, where R represents one roller, which can be a rubber roller or a steel roller.

Steel rollers are suitable for hard materials and with large sanding capacity.

Rubber rollers are relatively soft rollers. The outer layer is covered with wear-resistant rubber, and its thickness and hardness can be adjusted according to the customer's needs.

The wide belt sander is equipped with a Sand Belt Deviation System,Real time monitoring of the edge position of the sand belt to avoid unilateral wear or tear caused by lateral displacement. Ensure even contact between the sand belt and the workpiece.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.