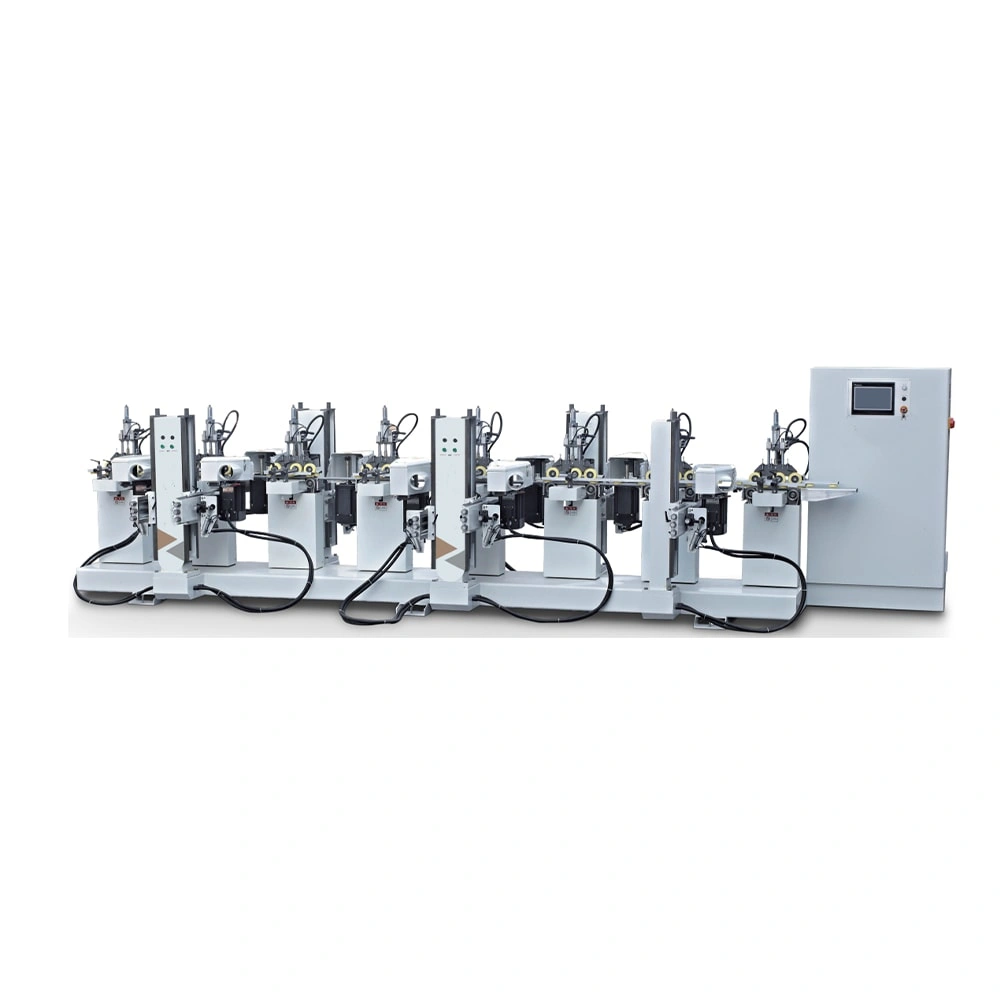

Four sides profile linear sanding machine with a scientific sanding method. The sanding of lines such as solid wood, artificial boards, veneer wood , and wood-plastic composites is mainly used for sanding white blanks, putty, primer sanding, topcoat polishing, as well as the edges of door core boards, cabinet boards, and door casings.

| Model | RM130D |

|---|---|

| Feeding width range | 20-230mm |

| Minimum workpiece length | 500mm |

| The thickness range of processed parts | 8-110mm |

| Feeding speed | 5-41m/min |

| Feeding motor power | 0.55*13kw |

| Main shaft motor power | 1.5kw*16 |

| Spindle configuration quantity | 16pcs |

| Automatic compensation device | 16pcs |

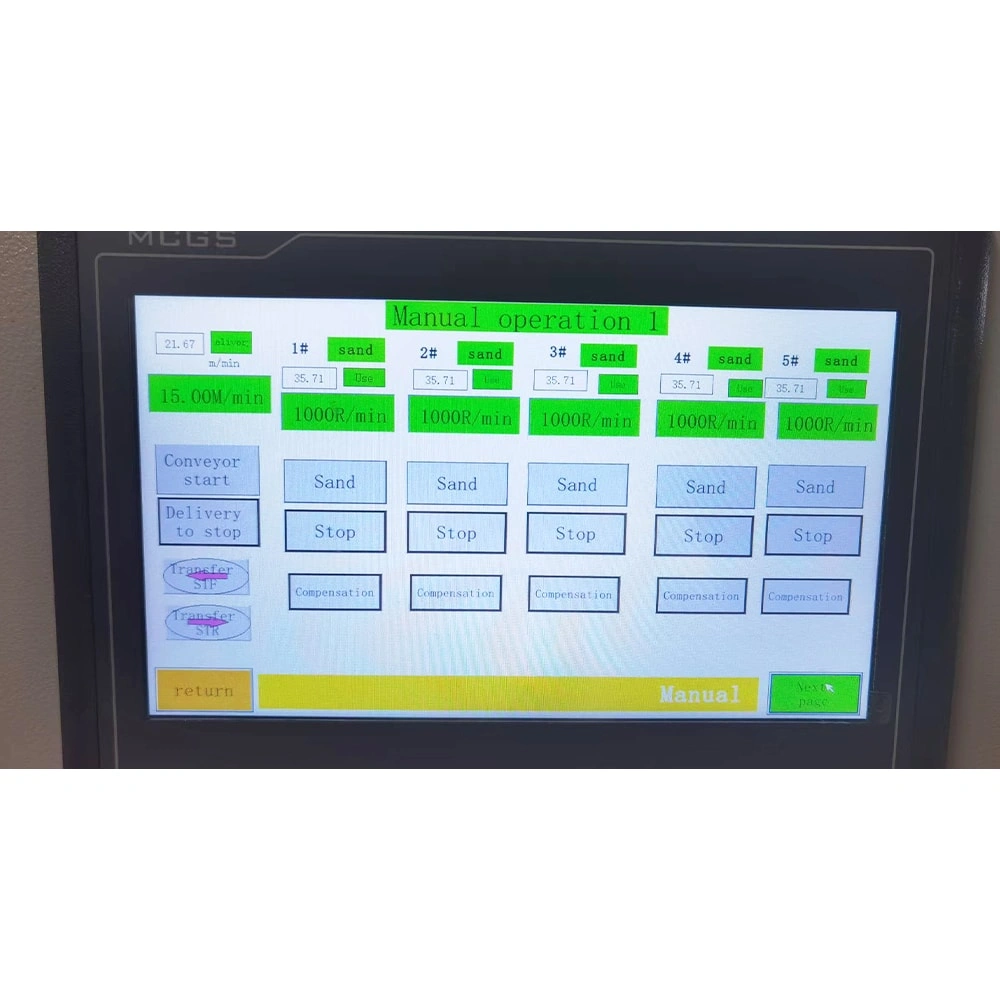

| Spindle speed | 300-1900r/min |

| Spindle rotation | Adjustable Angle |

| Main shaft dimensions (shaft diameter * length) | Φ25.4*100m*12 Φ25.4*150mm*4 |

| Grinding wheel size (outer diameter) | 200mm |

| Diameter of the suction port | 100mm |

| Working air pressure | 0.2~0.6Mpa |

| Total power | 31.15kw |

| Mechanical external dimensions | 9300*1500*1550mm |

| Weight | 4T |

Four sides profile linear sanding machine with a scientific sanding method. The sanding of lines such as solid wood, artificial boards, veneer wood , and wood-plastic composites is mainly used for sanding white blanks, putty, primer sanding, topcoat polishing, as well as the edges of door core boards, cabinet boards, and door casings.

Four sides profile linear sanding machine can use polyurethane polishing wheels, non-woven wheels, grinding wheels, abrasive belts, nylon wheels, octagonal sand, emery cloth strip wheels and other abrasive material to grind the surface of the workpiece in a flat or profile polishing.

Each polishing tool of the four sides profile linear sanding machine can be freely replaced with different types of polishing tools , and the first four polishing tools have the function of abrasive belt oscillation.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.