Wood veneer wide belt sander is a processing technique that physically grinds the surface of wood veneer through a sanding machine. By controlling the grinding amount (for example, fine sanding should be controlled at around 0.05mm), the thickness of the wood veneer can be made more uniform and the surface flatness can meet the requirements for bonding.

| Model | RMV130 | RMV60 |

|---|---|---|

| Max. Working width | 1300mm | 600mm |

| Working width range | 0.2-90mm | 0.2-90mm |

| The length of processing materials | ≥200mm | ≥200mm |

| Speed of abrasive belt | 0-18m/sec | 0-18m/sec |

| Feed speed | 3-25m/min | 3-25m/min |

| Power of 1st sanding unit | 15Kw | 5.5Kw |

| Power of 2nd sanding unit | 11Kw | 4Kw |

| Compressed air volume | ≥5000M3/h | ≥5000M3/h |

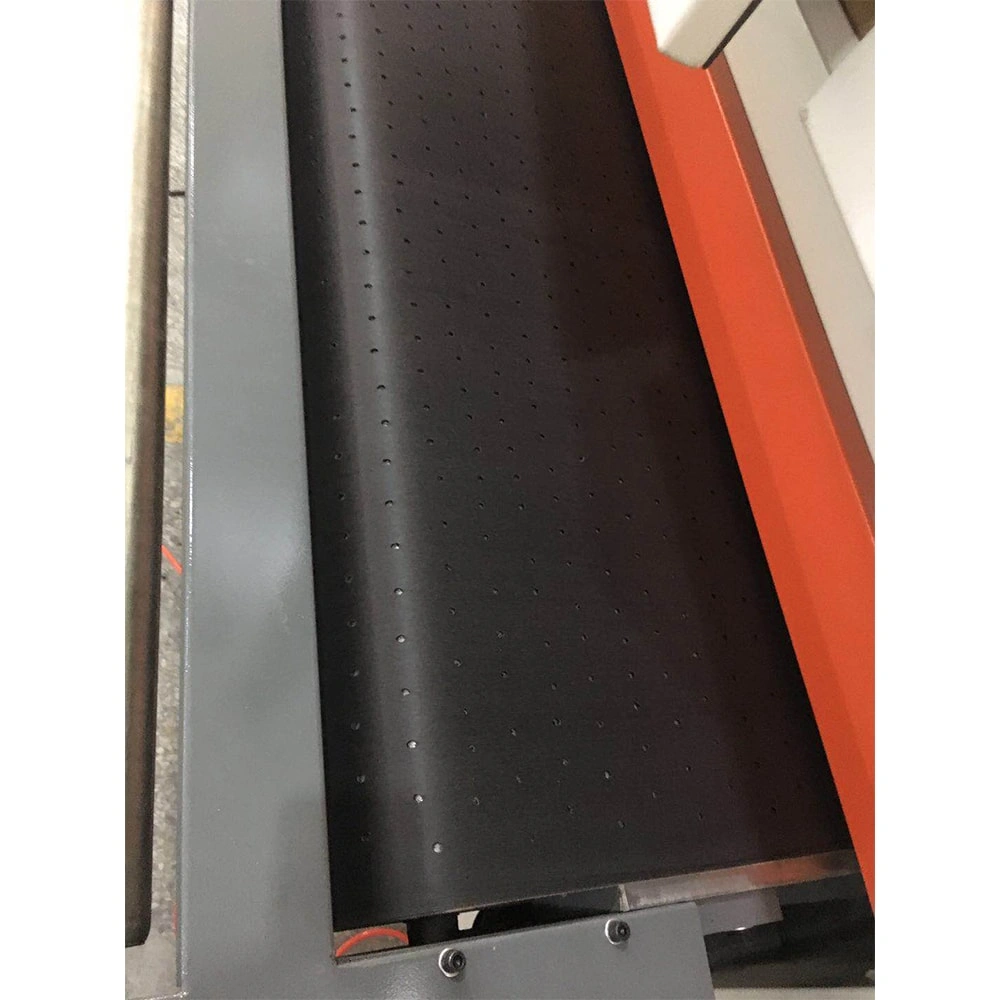

The veneer wide belt sander uses vacuum conveyor belt to attach the veneer to the workbench, and the soft sanding roller gently polishes the veneer to make the surface smooth.

Each roller of the veneer wide belt sander is equipped with a frequency converter, and the speed of the rollers can be adjusted according to the different thicknesses of the wood veneer.

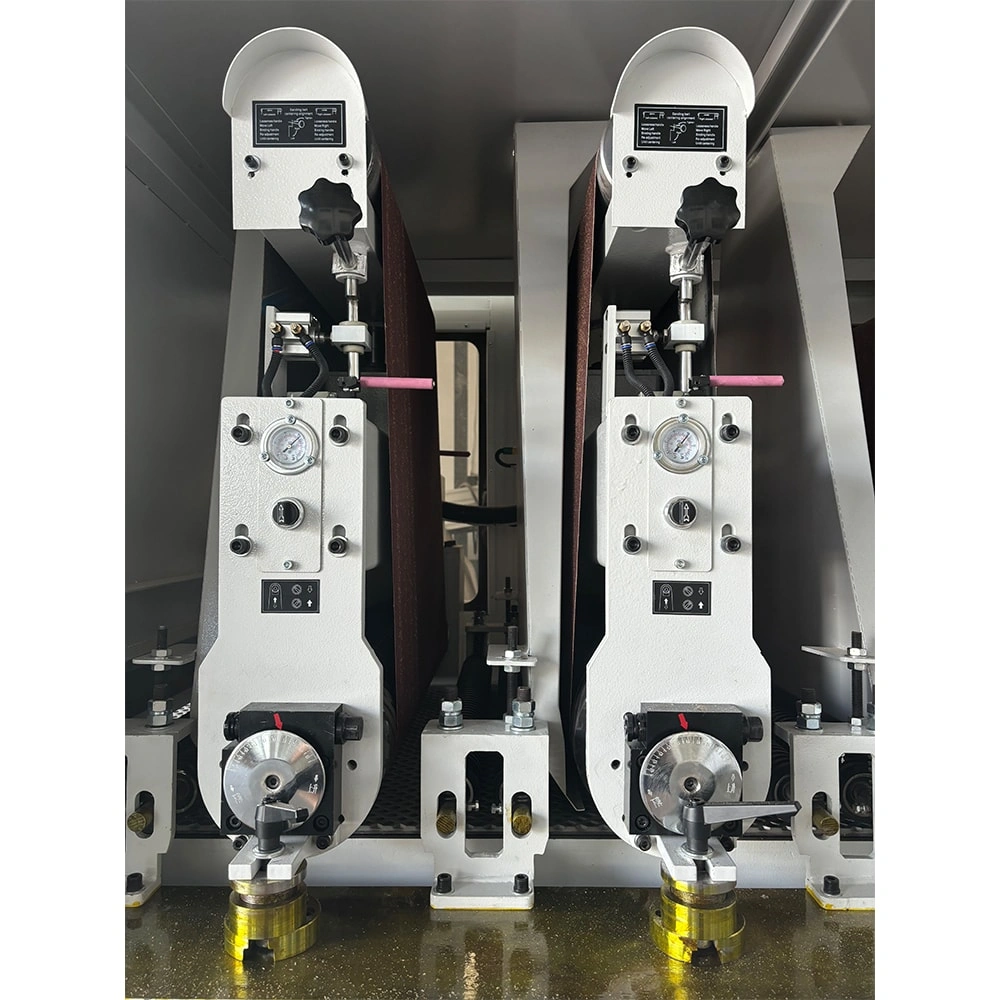

The most common veneer wide belt sander is the R-R structure, The two rollers are made of soft rubber material. Rubber is elastic and can deform slightly,which uses two rubber rollers to remove small burrs, dust, and minor defects that may be present in the veneer itself. By finely sanding, the natural pores and textures of the veneer are made clearer, more three-dimensional, and have a smoother texture.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.