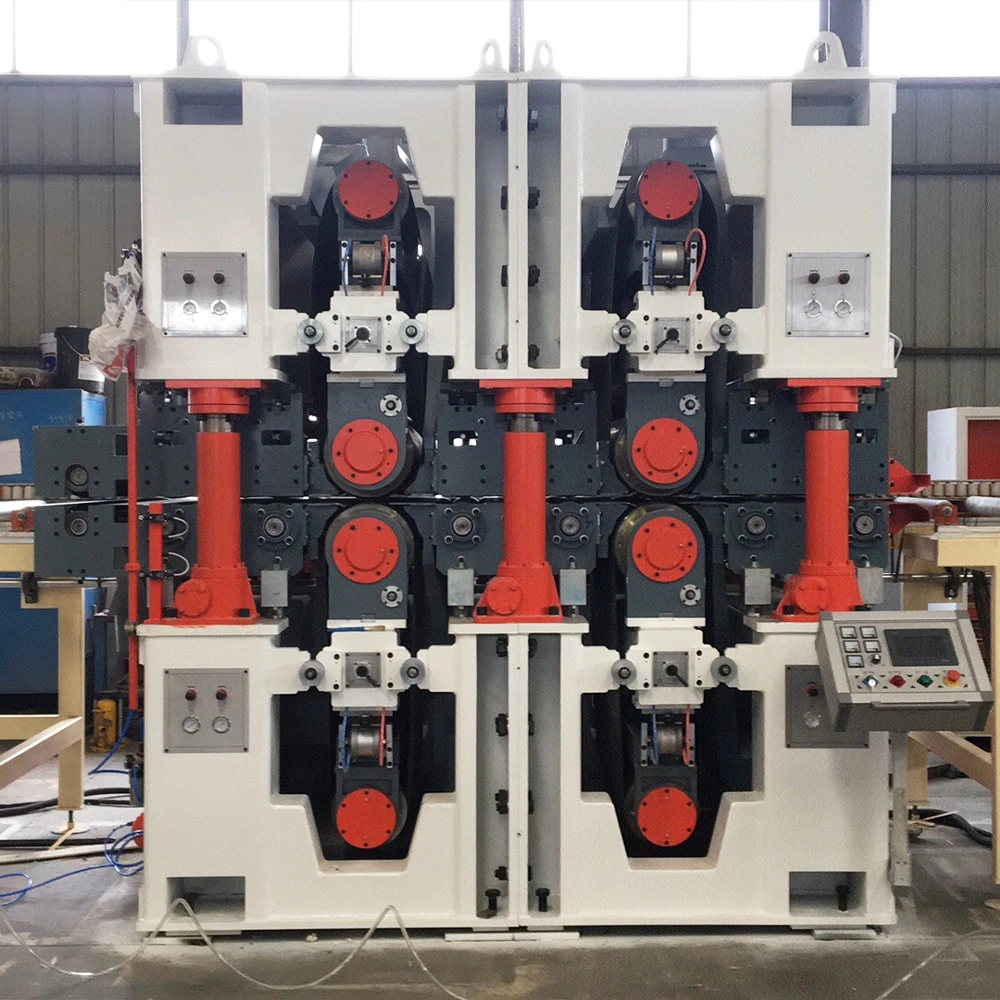

| Model | RM5613R |

|---|---|

| Max working width | 1300mm |

| working thickness | 5-100mm |

| Working length | ≥600mm |

| Feeding speed | 5-30m/min |

| working precision | ±0.08mm |

| size of abrasive belt | 1350*2800mm |

| speed of abrasive belt | 25m/s |

| Roller diameter | Φ320mm |

| Main motor power | 75Kw*2 |

| Feeding motor | 11Kw |

| Lifting motor | 2.2Kw |

| Brush motor | 0.75kw*2 |

| working air pressure | 0.5-0.8Mpa |

| volume of dust collector | 28000 m³/h |

| Weight | 11T |

Heavy duty double-sided wide belt sanding machine is a highly efficient and powerful wide belt sanding machine. Both sides can be sanded simultaneously.

Heavy duty double sides sanding machine series is unlimited by the original thickness tolerance. It is significant for the woodworking machinery to calibrate the wood-based panel and get the required thickness and precision through double-side sanding.High-precision (thickness tolerance with ±0.08mm after double-side sanding), top-quality, high efficiency (complete calibrating and polishing single-side or double-side of panel only once) are its advantage.

Heavy duty double sides sanding machine is mainly applied in calibrating and fine-sanding particleboard, block board, MDF, high-pressure overlaying board, multi-layer, cement particle board, medium or high density calcium silicate board and solid wood etc.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.