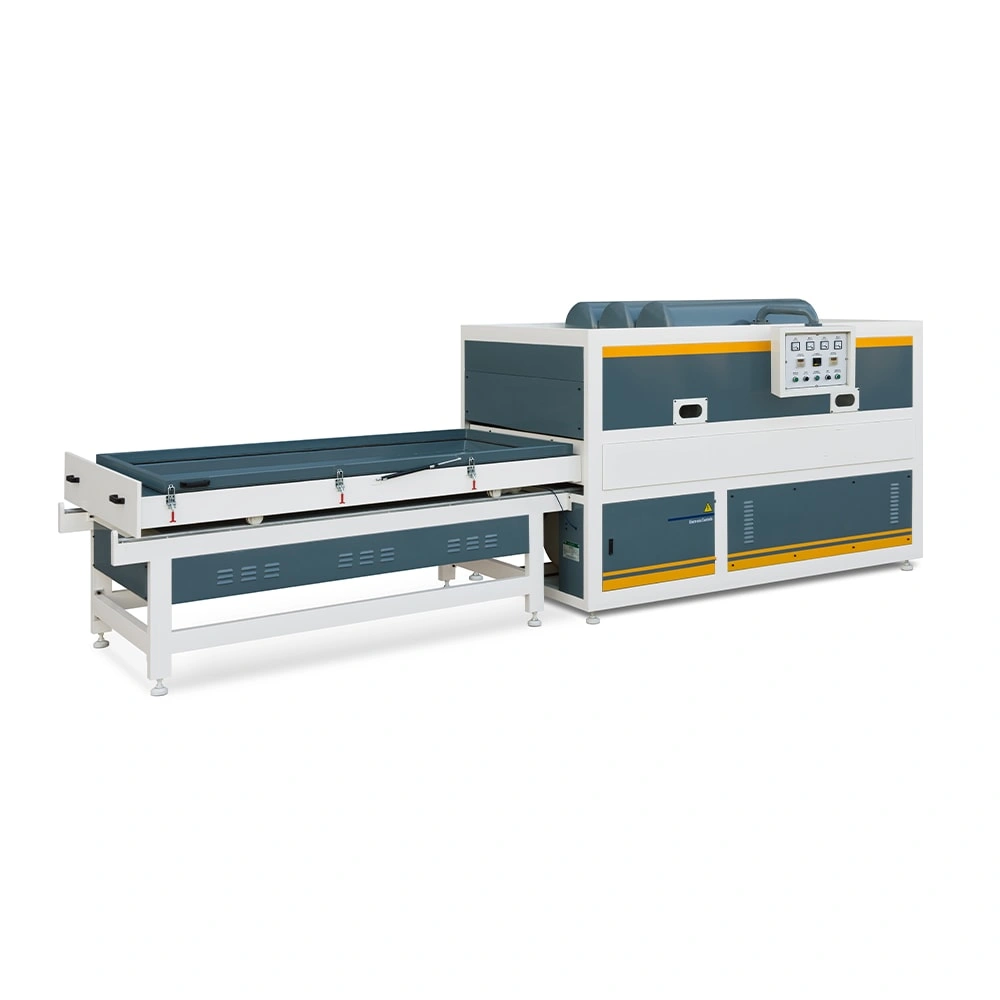

Vacuum membrane machine is an industrial equipment designed based on the principle of vacuum negative pressure, mainly used to attach PVC film to the surface of irregular workpieces. Widely used in furniture manufacturing and home decoration fields.

| Model | RM2300C |

|---|---|

| Overall dimensions | 5300×1800×1800mm |

| Worktable size | 2300×1100mm |

| Max. Workpiece size | 2150×1000mm |

| Total power | 23 Kw |

| Vacuum | -0.1Mpa |

| Weight | 1300kg |

Vacuum membrane machine is an industrial equipment designed based on the principle of vacuum negative pressure, mainly used to attach PVC film to the surface of irregular workpieces. Widely used in furniture manufacturing and home decoration fields.

Vacuum membrane machine with alarm system. after heating reached,it alarm to remind for next step or accident happen, we can stop in time and the light inside can be visible for see the PVC film or veneer changing.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.