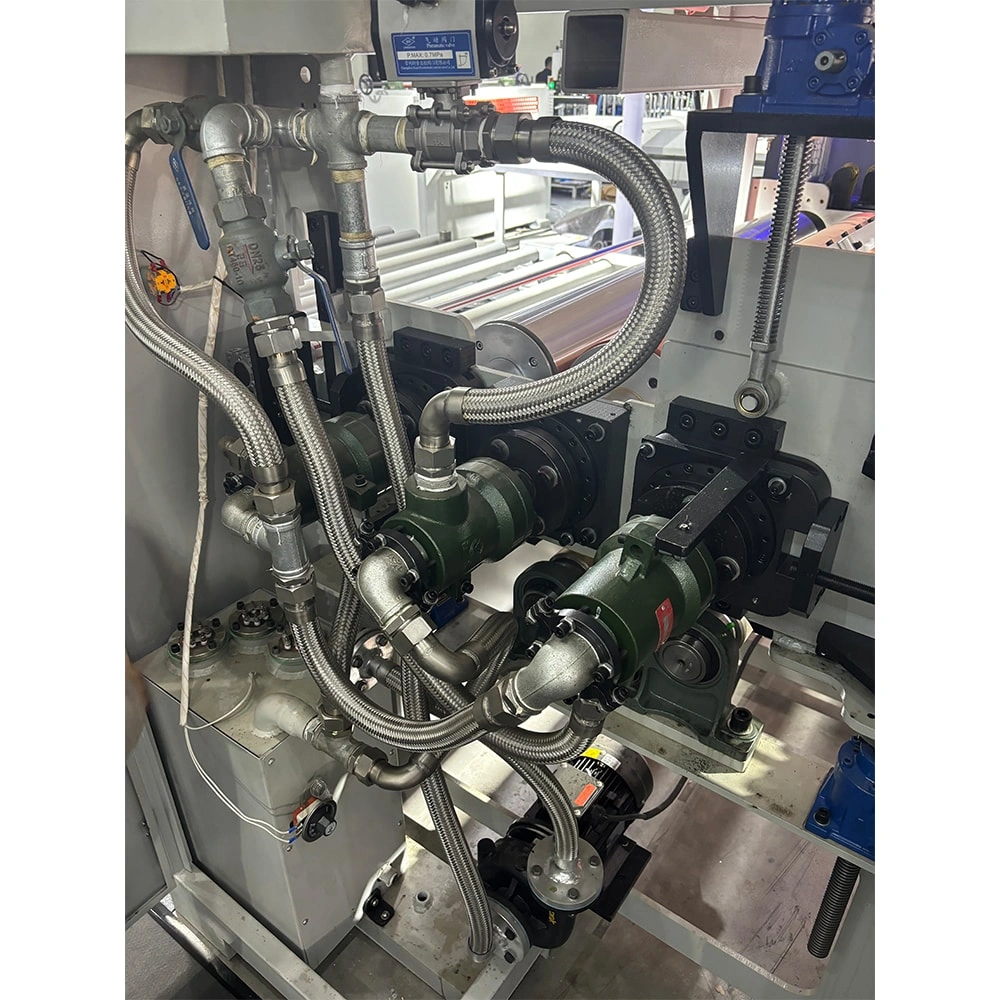

The heat transfer oil pump of PUR laminating line is the core power component of the heating system, responsible for circulating the heat transfer oil to transfer heat to the rollers, ensuring temperature uniformity and process stability. The material of the pump body can withstand the maximum working temperature of thermal oil ≥ 300 ℃, making it very safe to use.

| Model | RM1350-PUR |

|---|---|

| Max. panel width | 1220mm |

| Max panel thickness | 75mm |

| Max. feeding speed | 15m/min |

| PUR supply machine | 55 Gallon (13kw) |

| Gluing roll diameter | Ф240mm |

| Press roll diameter | Ф190mm |

| Control system | PLC touch screen |

| Total power | 65kw |

| Overall dimensions | 13000*2500*2550mm |

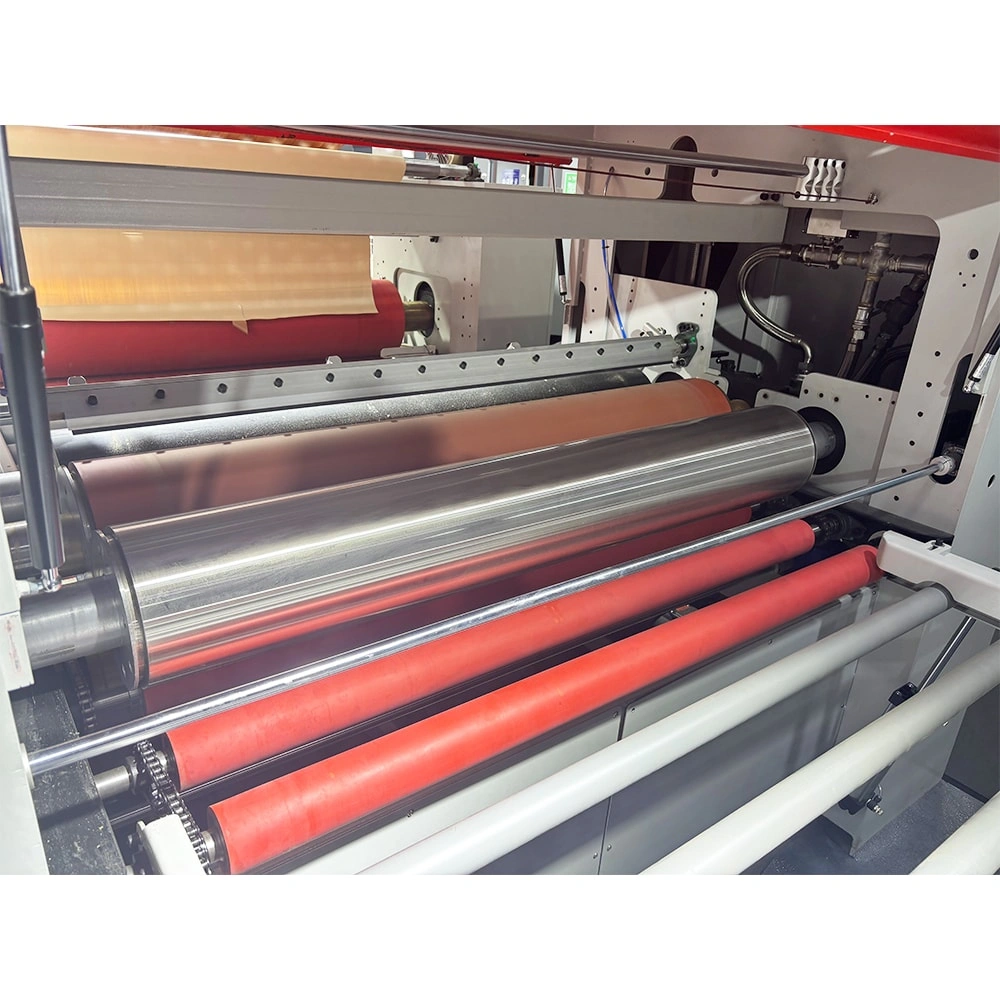

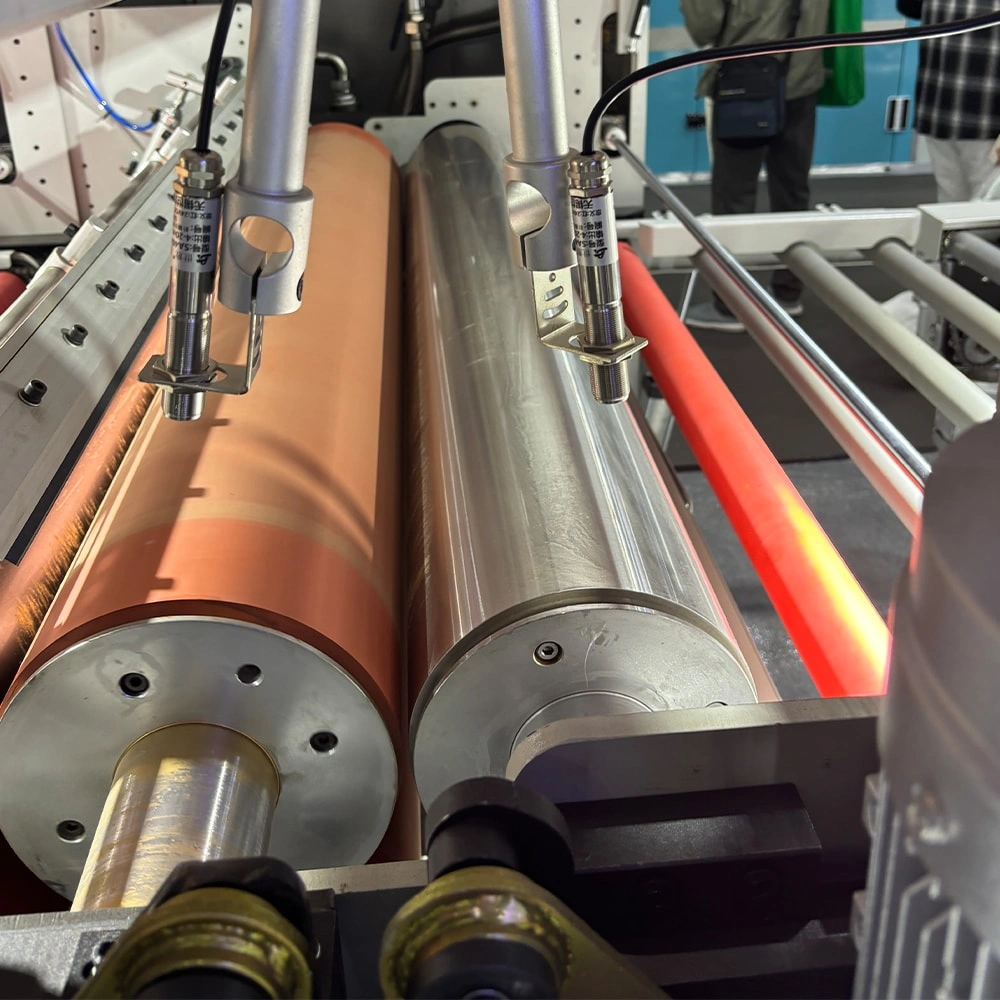

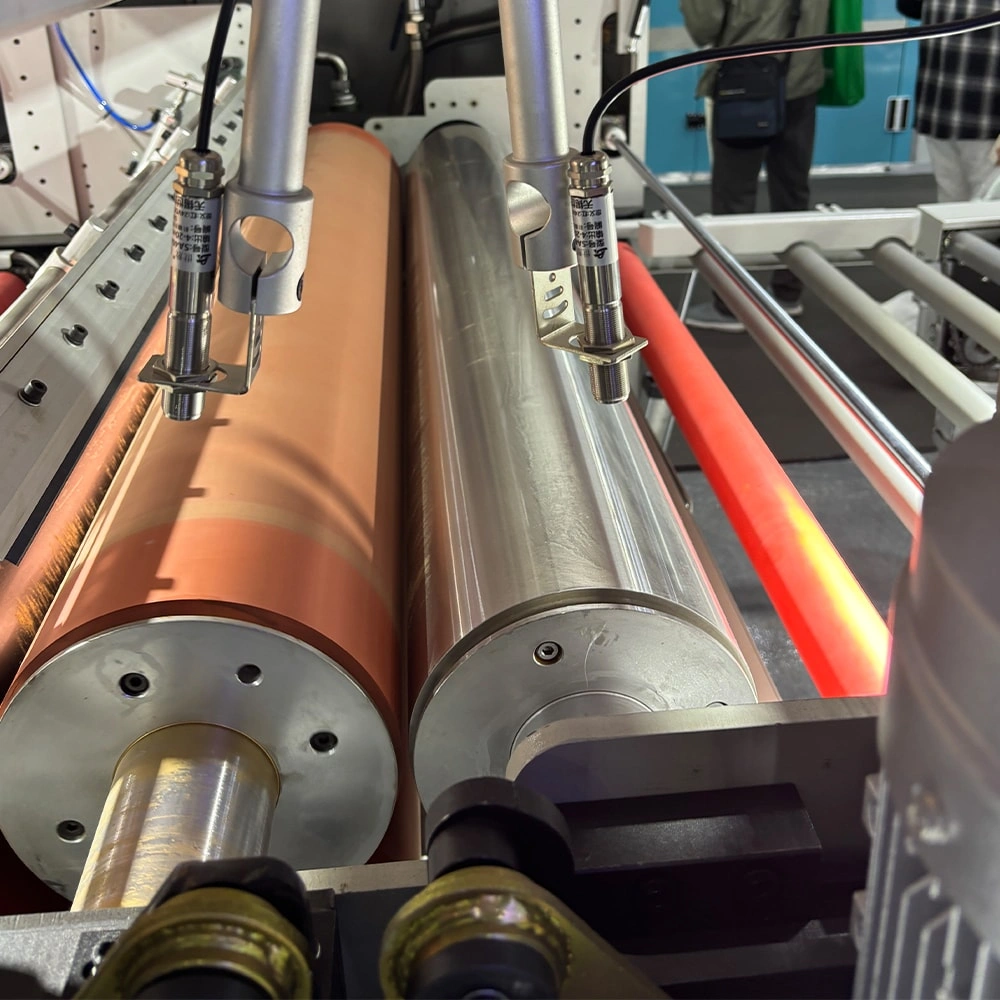

This PUR Laminating line is used to laminate high glossy film, acrylic panel, PVC panel, PVC film, paper, PET film, on MDF, plywood, PVC panel and other panel.The glue-coated roller adopts ceramic-coated roller, which has high surface hardness, wear resistance and long service life.

The PUR Laminating line is equipped with a 6-meter-long infrared heating device. It directly heats the material surface through infrared radiation, featuring strong penetration and fast heating speed. It can make the temperature of the sheet reach 40 degrees.

55 Gallon PUR Gluing Machine,Heating and melting solid PUR adhesive particles, equipped with an internal mixer to prevent sedimentation. In the PUR Laminating line, the gluing roller is one of the core components, and its performance directly affects the uniformity of the glue application, the thickness of the glue layer and the bonding quality.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.