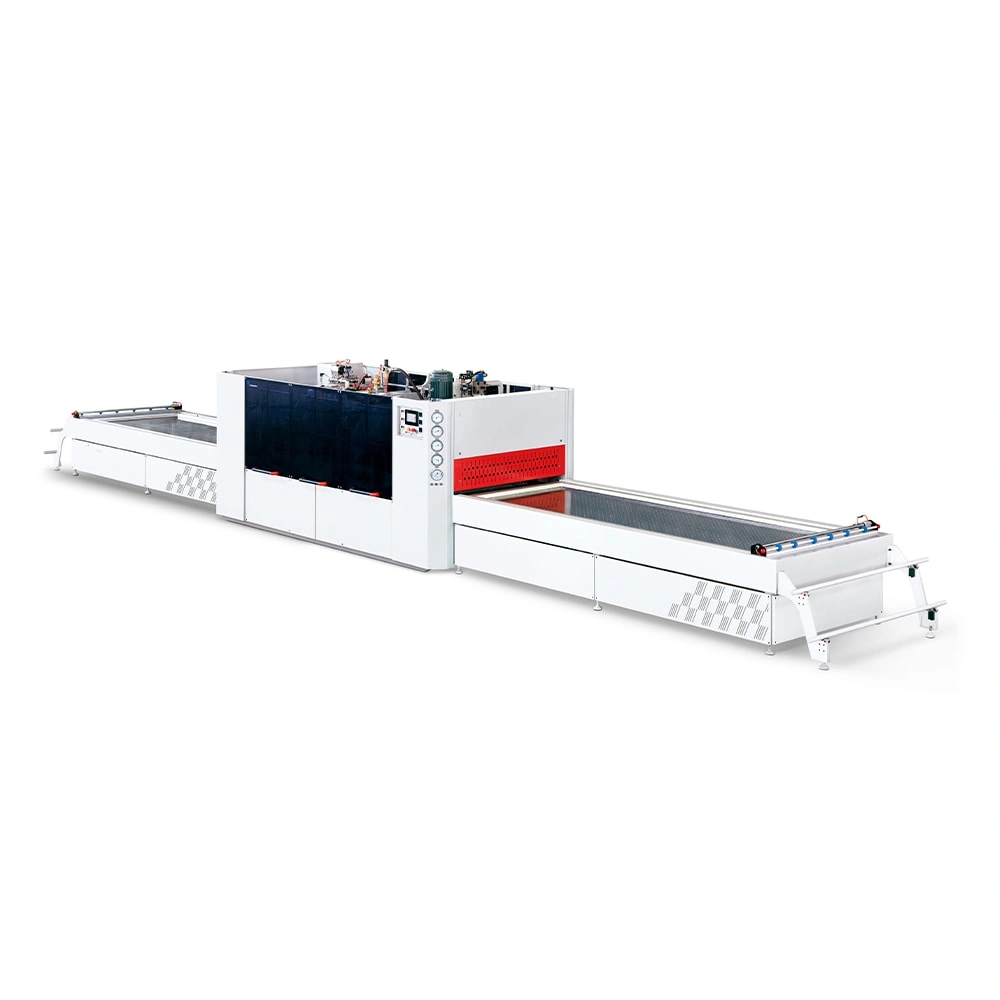

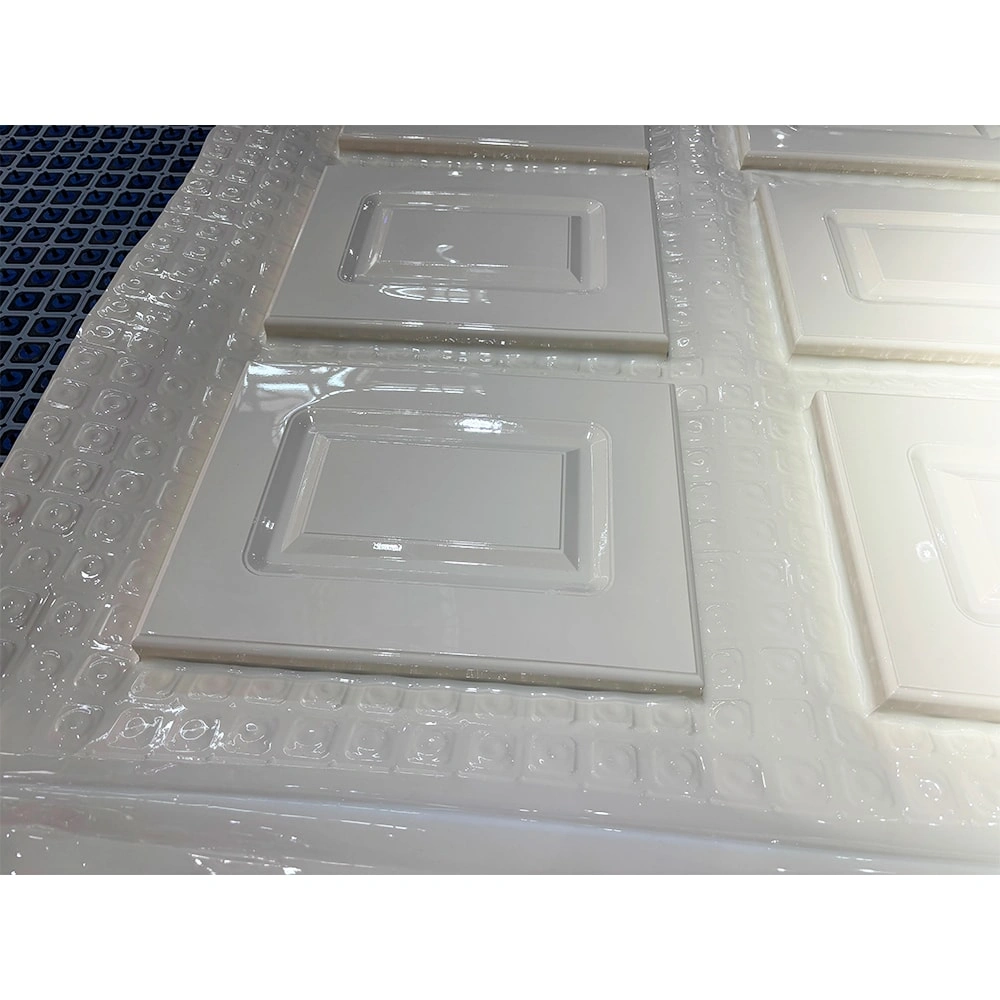

The positive and negative pressure vacuum machine simultaneously applies vacuum negative pressure and positive air pressure. The air between the worktable and the PVC vacuum forming film is rapidly extracted to form a vacuum. Then, compressed air is injected between the PVC vacuum forming film and the heating plate. Under the action of the set pressure and temperature, the PVC film is wrapped around the board.

| Model | RM2580A |

|---|---|

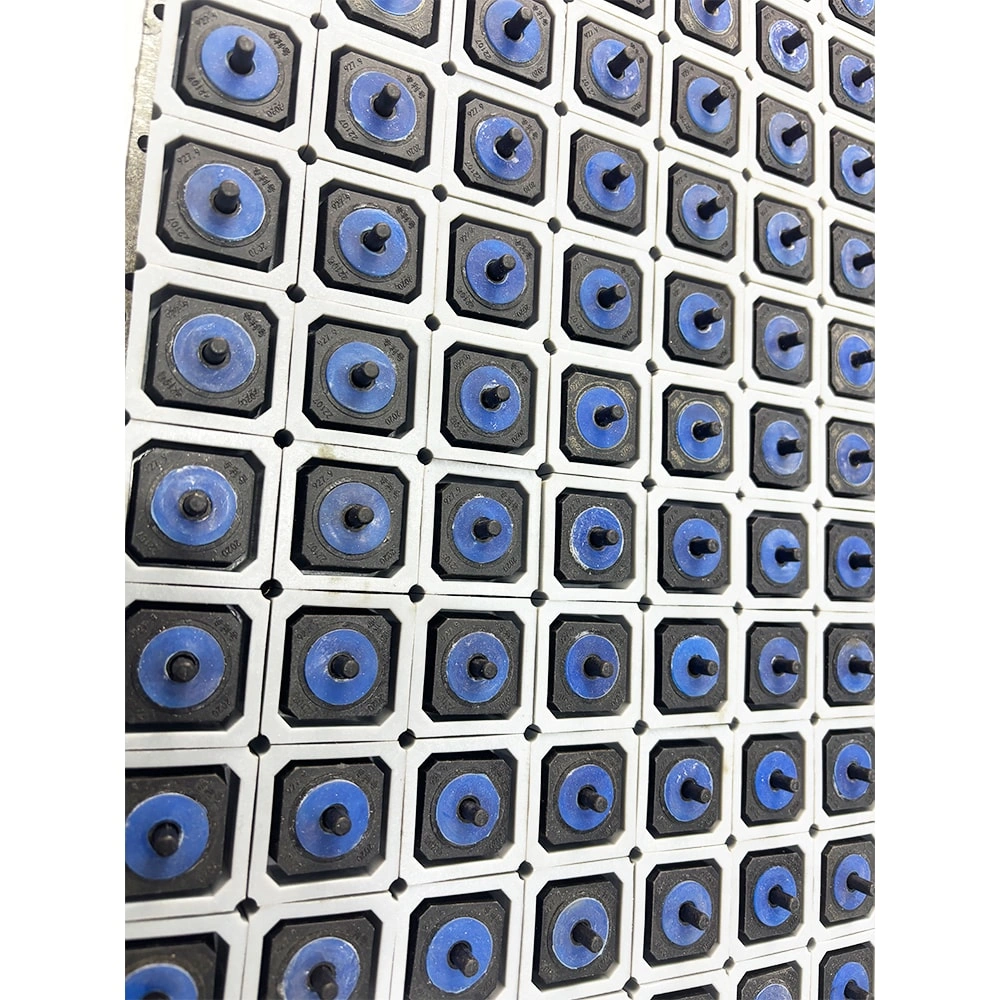

| Worktable size | 2580×1280mm*2 |

| Max work piece size | 2500*1220mm |

| Total power | 57.2Kw |

| Heating method | Oil heating(up); aluminum & electric(bottom); electric (Air heating) |

| Cylinder size | φ180mm*6pcs |

| Positive pressure | 0.4-0.5Mpa |

| Negative pressure | 0.08Mpa |

| PVC Cutting system | 2sets |

The positive and negative pressure vacuum machine simultaneously applies vacuum negative pressure and positive air pressure. The air between the worktable and the PVC vacuum forming film is rapidly extracted to form a vacuum. Then, compressed air is injected between the PVC vacuum forming film and the heating plate. Under the action of the set pressure and temperature, the PVC film is wrapped around the board.

The positive and negative pressure vacuum machine equip with pressure preparation heating device and automatic cooling system can make sure of high quality of products.Automatic double aluminum alloy working table can double the working efficiency.

Advanced man-machine interface and large scale of PLC control can make sure of high level of automation ,The positive and negative pressure vacuum machine more easy operation.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.