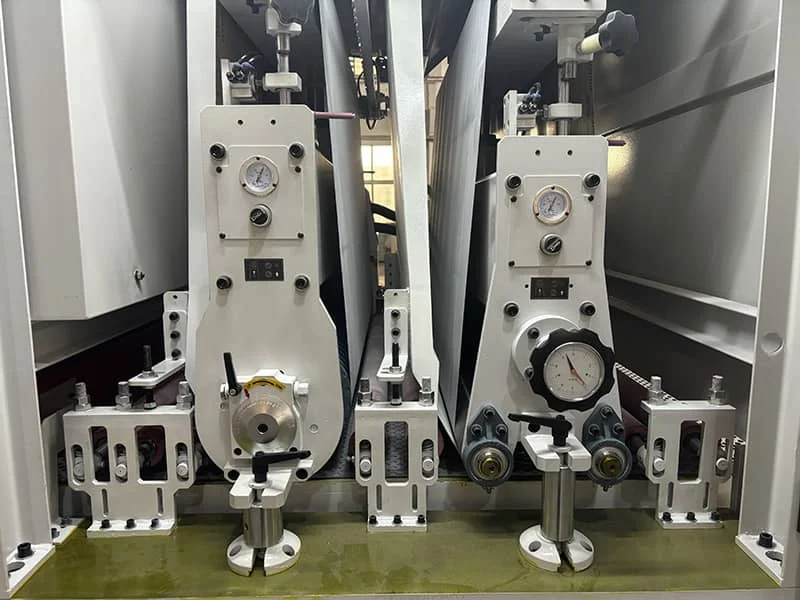

The RMQ series independently developed by our company is specially designed for the Lacquered Panel Sander,The usual machine structure is R-P, which R is a rubber roller and P is a sanding pad.

The hardness of the rubber roller is the core point. The harder the material . Harder rubber rollers are selected, but they have poor adaptability to the surface of the workpiece. The softer the material, the softer the rubber roller should be.High-quality rubber rollers will undergo precise dynamic balance correction. After dynamic balance correction, the vibration during Lacquered Panel Sander operation will be effectively reduced, which is crucial for achieving high-precision sanding effects.

The sanding pad is a sponge attached to the sandpaper, which has a certain degree of elasticity and softness, good cushioning performance, and can effectively prevent the paint layer from being worn through.Fine sandpaper is usually used to Lacquered Panel Sander. Sandpaper that is too coarse will leave deep scratches.Sanding the primer will produce very fine dust. A high-power dust collector is needed to effectively remove dust.

Adjusting the rotational speed of the rollers is also a very important step,If the primer is relatively hard, increase the speed of the roller and use coarser sandpaper to quickly remove the excess primer and improve efficiency. If the primer is relatively soft, reduce the roller speed and use finer sandpaper to avoid piercing the paint.For instance,some water-based primers or putties have relatively soft materials. Excessively high rotational speed can soften the material due to heat generated by friction,Causing sandpaper blockage of Lacquered Panel Sander and damaging the already ground smooth surface. When grinding soft materials, it is essential to use a lower rotational speed. The operator can select the optimal rotational speed and sandpaper grit based on the dust and sound produced during sanding.