The Edge Bander is one of the core equipment in the panel furniture production line. A fully automatic edge banding machine usually integrates the following specific functions: pre-milling, gluing, end cutting, rough trimming, fine trimming, corner trimming, edge scraping, and polishing.

Pre-milling: Before the panel is applied with adhesive, the edges of the panels are trimmed using a high-speed rotating milling cutter. It is the edge that reaches a perfect reference plane.

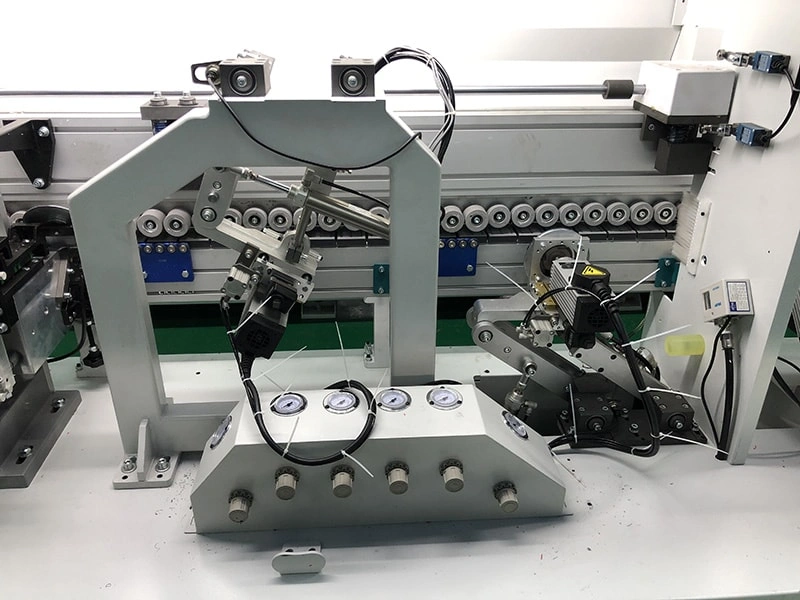

Gluing: The Edge Bander heats and melts the granular hot melt adhesive, and then evenly applies the adhesive to the edges of the panel through a precise gluing wheel.

End cutting:The End cutting device will precisely cut off the excess edge tape at the front and back ends of the panel, making the edge tape flush with the edge of the panel.

Rough & fine trimming:After the edge tape is pressed and pasted, both sides of the edge tape will be wider than the plane of the panel. The rough and fine trimming devices will trim off the excess edge tape on both sides to make them flush with the panel surface.

Corner trimming:For the parts with irregular grooves on the panel material, the corner trimming function enables the trimming knife to automatically perform special trimming.

Edge scraping:The scraper can remove the tiny glue lines remaining at the joint between the edge tape and the panel surface, making the joint cleaner and more aesthetically pleasing.

Polishing;The Edge Bander Use a cloth wheel to perform high-speed polishing on the finished edge banding joint to eliminate the possible fine scratches caused by edge trimming and make the gloss of the edge banding consistent with that of the board surface.

Select appropriate functions based on different product processes to achieve perfect product effects.

When using a four-sided planer, factories typically have two options: square four-sided blades or rectangular double-sided blades. How should you choose the right blades for your needs? Below, I will explain based on my experience.

If the thickness of the veneer is less than 3mm, you will need a veneer wide belt sander. Two soft roller structure sanders are particularly suitable for sanding veneer. Generally, veneer is very thin, and the sandpaper can easily tear through it. By adjusting the roller speed and conveyor belt speed, the sandpaper can avoid cutting through the veneer.

The tools store is a device on a CNC router used for storing and automatically changing tools. It is like a "tool warehouse", automatically removing the current tool from the spindle according to the instructions of the processing program and installing the tools required for the next process.

The 3D scanning spray painting machine, by integrating 3D vision scanning, intelligent path planning and precise spraying, is suitable for door panels with complex shape, significantly enhancing the automation level and quality of door panel spraying.

The greatest advantage of the CNC vertical panel saw lies in its ability to fix large sheets of board almost vertically on a sturdy frame. The saw blade rotates at high speed and moves horizontally to complete the cutting of the upright board.

The Veneer Wide Belt Sander is a device designed for large-scale, high-efficiency, and high-precision surface treatment of veneer. It can sand veneer as thin as 0.1mm.

The stability of the CNC Bean Saw is the key to ensuring its long-term efficient and precise operation. Use materials with sufficient strength and rigidity, and ensure the stability of the foundation through reasonable welding and reinforcement processes.

PUR Laminating Line is used to attach PVC, PP, PET film, decorative paper, thin wood veneer and other materials onto flat base material.The entire line is fully automated and connected, with a fast production rhythm and huge production capacity, which greatly reduces labor costs and labor intensity.

A multi-rip saw is a machine that can cut wood into multiple pre-adjusted widths at one time and is a highly efficient machine.The safety of the equipment is the most crucial aspect. This type of equipment combines high speed, high power and sharp cutting tools. Any negligence may cause serious accidents.

The Vacuum Membrane Press is a device that uses an electric heating and vacuum pumping system to adsorb thermoplastic sheets or wood veneers onto workpieces. This machine is mainly composed of a heating system and a vacuum pump.

No.9 LIAOYANG EAST ROAD , QINGDAO, CHINA

Copyright © 2025 by Qingdao Ruimuda Machinery Co., Ltd. All Rights Reserved