The CNC beam saw is equipped with optimization software that can help operators optimize cutting options. It features automatic feeding, automatic positioning, and automatic cutting. The high-precision servo system controls the feeding accuracy, and the electronic ruler performs precision compensation. This effectively ensures the integrity of the sawn end face of the board while improving work efficiency.

| Model | RMJ330 | RMJ380 |

|---|---|---|

| Cutting length | 3200mm | 3800mm |

| Working area | 3200*3200mm | 3800*3200mm |

| Maximum height of saw blade | 120mm Intelligent lifting | 120mm Intelligent lifting |

| Cutting thickness | 0-90mm | 0-90mm |

| Feeding speed | 0-80m/min | 0-80m/min |

| Cutting speed | 0-100m/min | 0-100m/min |

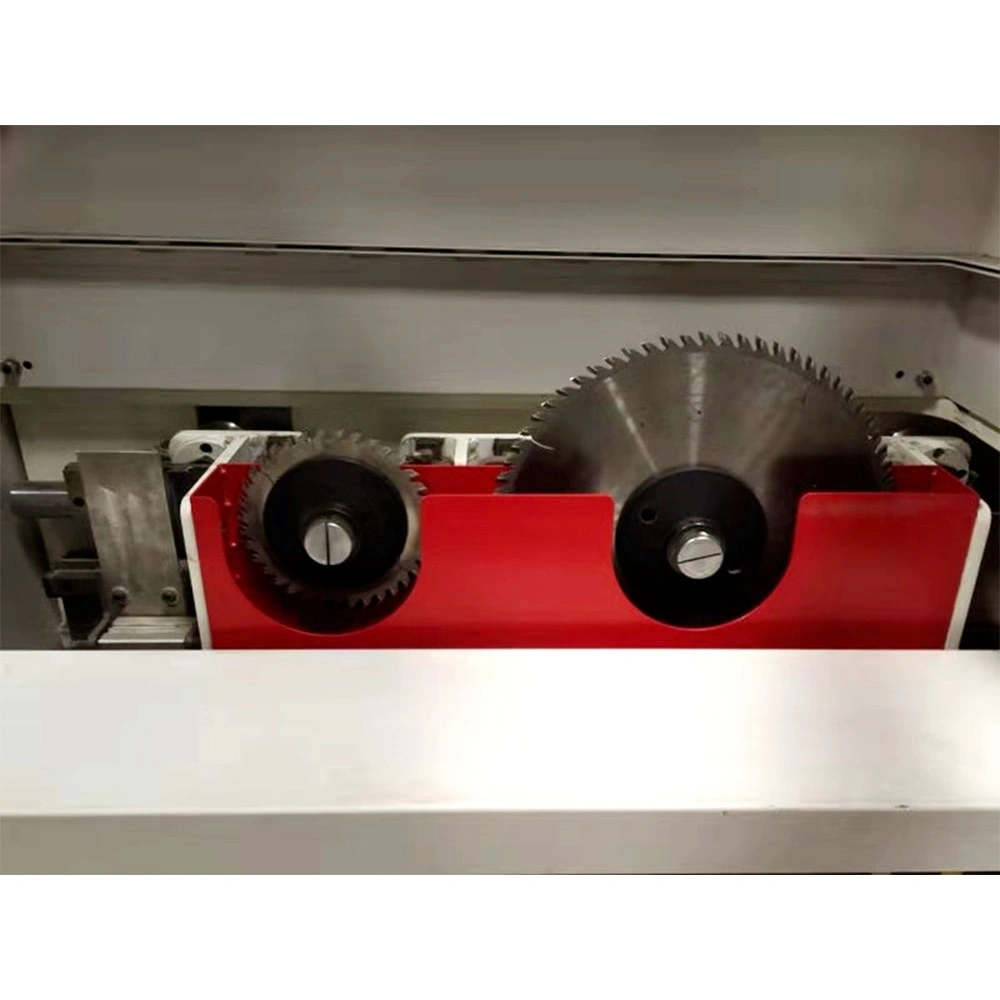

| Main saw diameter | 380mm/400mm | 380mm/400mm |

| Inner hole of main saw blade | 60mm | 60mm |

| Scoring saw diameter | 180mm | 180mm |

| Inner hole of scoring saw blade | 45mm | 45mm |

The CNC Beam Saw used in density board, particleboard, medium fiber board, gypsum board, artificial stone, plexus glass, large core board, light guide board, aluminum board, aluminum plastic board, circuit board, solid wood and other boards precision cutting.

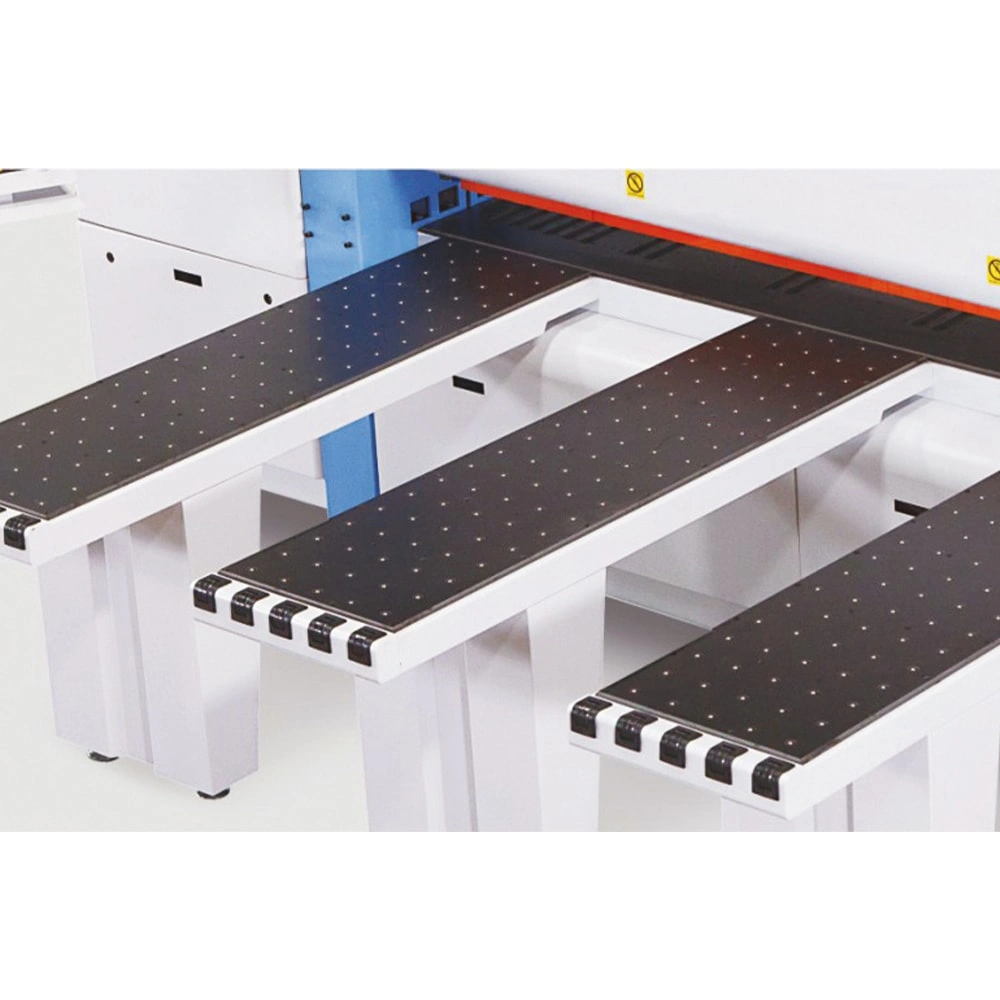

The CNC Beam Saw is equipped with an automatic feeding device and human-machine integrated operation. Workers input the required size data on the touch screen, start the machine, and the machine runs automatically. At the same time, it is equipped with an air floating bead table to avoid friction and wear between the workpiece and the workbench.

The driving system of CNC Beam Saw adopts servo control and gear rack drive, running smoothly. The saw stroke can be automatically adjusted according to different cutting lengths, reducing the empty stroke and improving the working efficiency.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.