Compared with the ordinary sander, the Wide Belt Planer Sander is equipped with a spiral planer knife. The wood board is first planed with a layer by the planer knife and then finely ground by the sanding roller.

The advantages of the spiral planer knife are as follows:

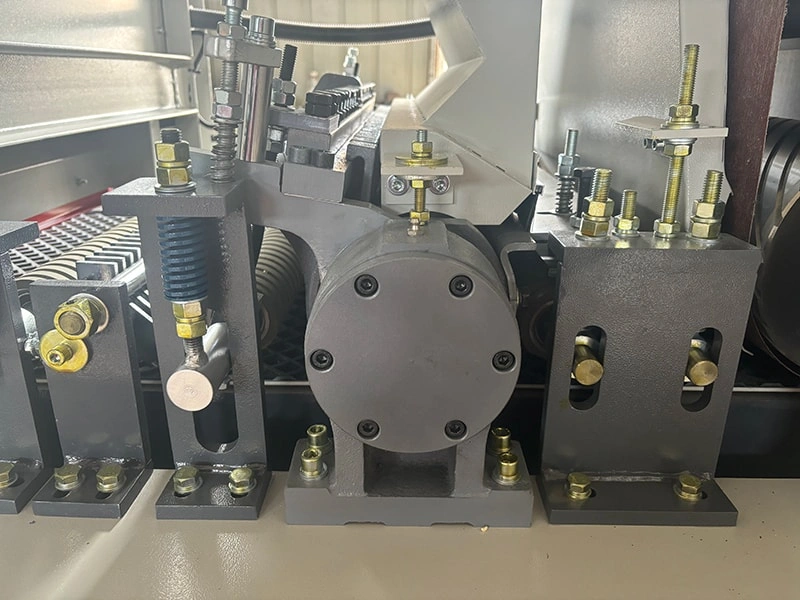

1. Compared with the traditional straight knife, when the entire blade strikes the wood simultaneously, it will produce a continuous and sharp noise.Then the blades of the spiral knife are segmented. At any given moment, only a few small blades are in contact with the wood, which reduces the noise

2. The maintenance cost of the spiral planer knife is lower. The shape of the blade is square and usually has four sharp cutting edges. If a certain cutting edge is damaged, simply rotate this blade by 90 degrees.

3. The spiral planer knife are more energy-efficient because the blades are segmented. The entire knife shaft operates very smoothly at high speed, with uniform load and minimal impact on the motor.

The Wide Belt Planer Sander combines two independent processes, namely "first thickening through pressure planing and then sanding through a sanding machine", in one piece of equipment to complete at one time. Time-saving: It eliminates the time for intermediate transportation and equipment adjustment. The board only needs to be used once to achieve the desired effect for the customer.

The sand planer is mainly used for cutting the rough and uneven surface of wood to make it smooth, and processing the thickness of the entire board to an exact and consistent size.Ordinary sanding machines cannot correct plates with excessive thickness deviations. If you directly sanding the curved part, only the protruding part will be ground off, but the board will still bend. The Wide Belt Planer Sander uses a spiral planer knife to first correct the board to a uniform thickness, and then performs sanding.