Automatic Wood Texture Wire Brush Machine is a processing method that uses steel wire rollers and nylon rollers for processing. It is applicable to the antique and aging processing of various types of boards such as solid wood, veneer, and wood-plastic boards. To simulate the natural texture and feel of wood, thereby enhancing the aesthetic appeal and added value of the product.The high-speed rotating steel wire roller comes into contact with the surface of the wood. Through slight friction, it leaves texture of varying depths and widths on the wood surface. When these texture are combined, they form the visual wood grain effect.

The Wood Texture Wire Brush Machine are usually equipped with steel wire rollers, nylon rollers and brush rollers. A single sand head is difficult to create a realistic, three-dimensional and high-quality wood grain effect. By combining different rollers, the depth, width and glossiness of the wood surface cutting can be precisely controlled, thereby simulating the original texture of the wood.

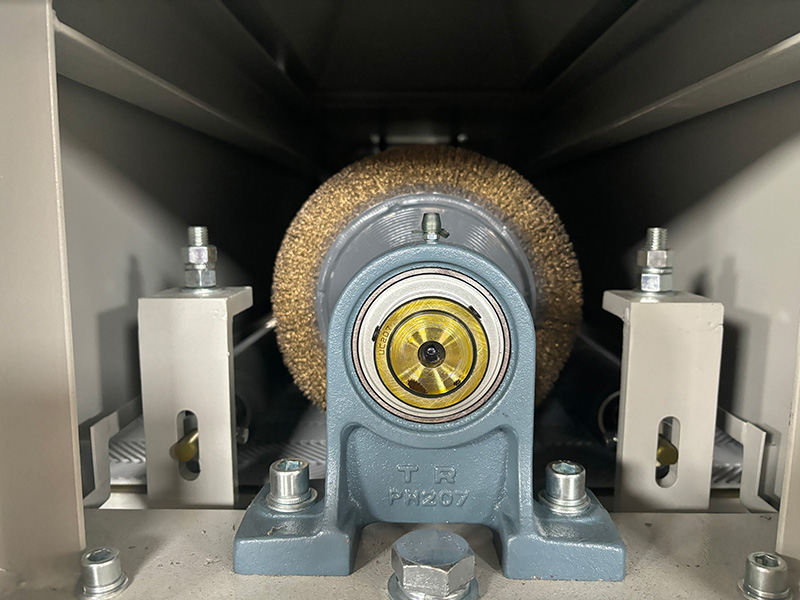

Steel wire rollers are composed of tens of thousands of dense and neatly arranged steel wires on the main shaft. The diameter, density and hardness of the steel wire will all affect the texture effect of the wood board.The function of the nylon roller is to polish the raised surfaces with existing textures to a very bright finish, while keeping the "recessed" parts relatively dark, creating a strong contrast between light and dark, and making the three-dimensional effect of the texture distinct.Steel wire rollers and nylon rollers are the two most important components of the Wood Texture Wire Brush Machine.

Compared with manual wire drawing, automatic Wood Texture Wire Brush Machine can grind the texture requirements that customers want in one go. Customers can choose different numbers of rollers and different types of rollers to meet their own requirements.If your work involves the manufacturing of solid wood furniture, the processing of wooden floors or interior decoration, and you want to create products with three-dimensional texture and touch, then this machine is a very worthy option to consider.