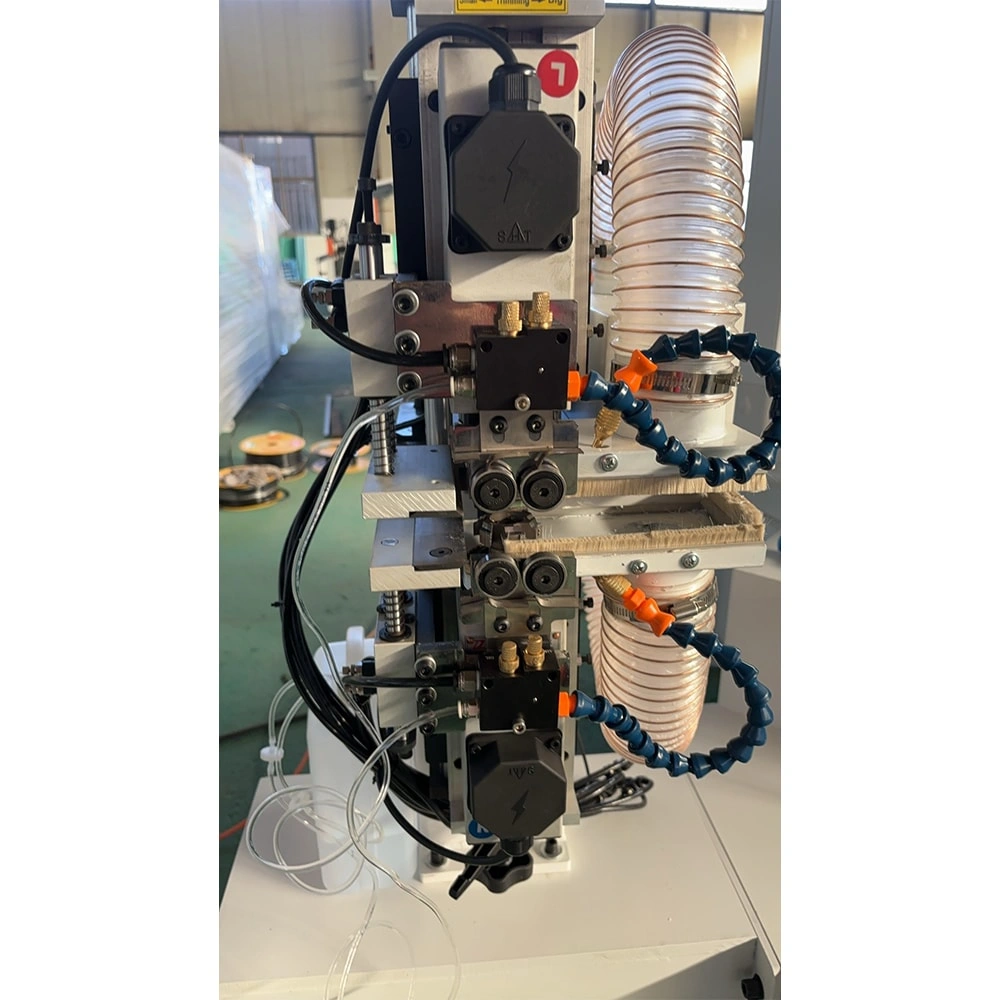

The Curved and straight edge bander is suitable for round, oval and rounded rectangular plates. Equipped with automatic feeding, laser ranging, precise docking, high precision, and no need for manual cutting of strip materials. The servo motor features fast action response and low noise. The machine has good stability.

| Model | RM615A |

|---|---|

| Edge belt thickness | 0.5-3mm |

| Edge belt width | 15-50mm |

| Work piece radius | 150-1200mm |

| Min curve working radius | 20mm |

| Feeding speed | 0-11m/min |

| Total Power | 3Kw |

| Heating power | 1.6Kw |

| Working air pressure | 0.55mpa |

The Curved and straight edge bander is suitable for round, oval and rounded rectangular plates. Equipped with automatic feeding, laser ranging, precise docking, high precision, and no need for manual cutting of strip materials. The servo motor features fast action response and low noise. The machine has good stability.

tray arm device designed to mimic ergonomics, with a flexible rotating structure for operation;Strong suction cup: firmly adhere to the board, prevent hanging and sagging.

The Curved and straight edge bander capacity of the glue pot is increased to 2600ml, and there is no need to add glue frequently. Heat preservation function of the glue pot reduces the waiting time for heating by one-click.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.