| Model | RM416A | RM421A |

|---|---|---|

| Working width | 15-160mm | 15-210mm |

| Working thickness | 8-100mm | 8-100mm |

| Work table length | 1600mm | 1600mm |

| Feeding speed | 10-45m/min | 10-45m/min |

| Main spindle diameter | Φ40mm | Φ40mm |

| Rotary speed of main spindle | 6800r/min | 6800r/min |

| Air pressure | 0.6MPa | 0.6MPa |

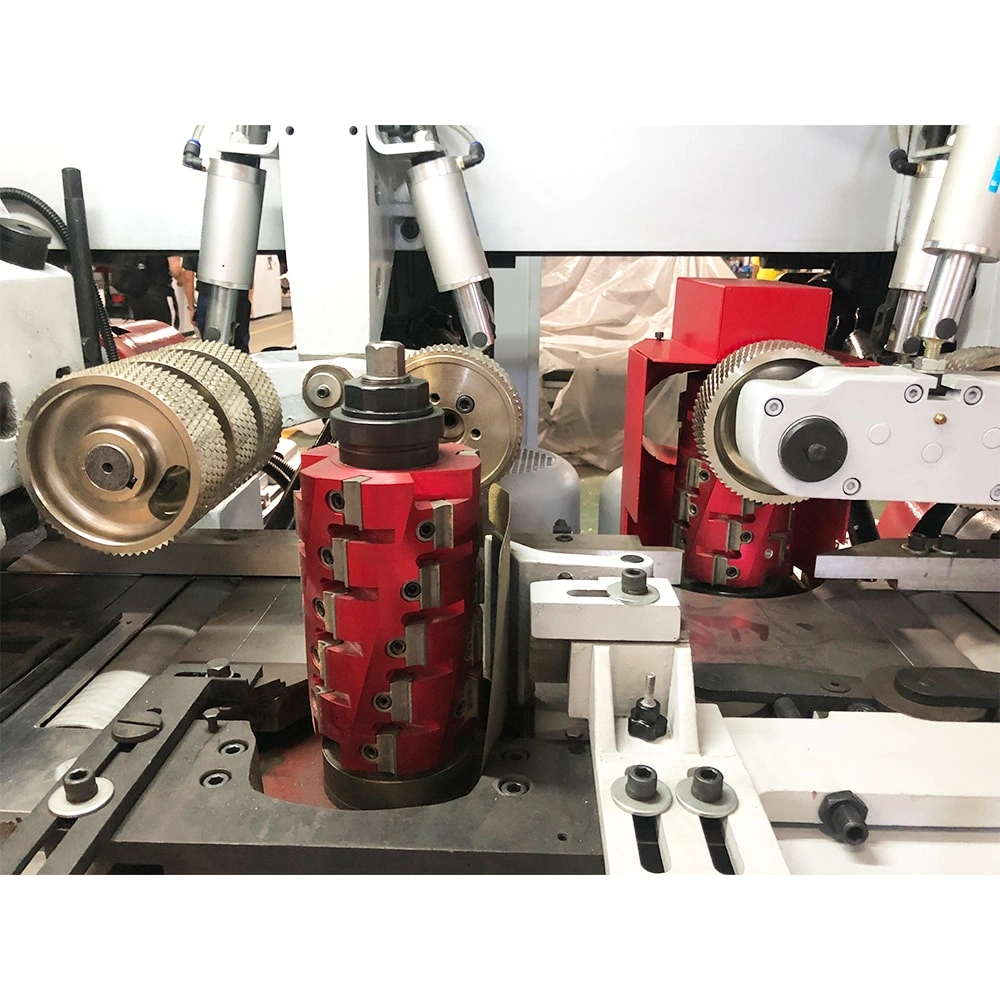

The 4 spindles four sided planer moulder is an industrial wood mechanical processing equipment, mainly used for four-sided planing processing of wood.

The 4 spindles four sided planer moulder has a total of four main spindles. The main spindlet is one of the core components of the equipment, responsible for driving the tool to rotate at high speed to complete processes such as wood planing, shaping, and slotting.

The electronic components of the four sided planer moulder are the core part for achieving automation and high-precision machining, involving multiple aspects such as control systems, drive modules, and safety protection.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.