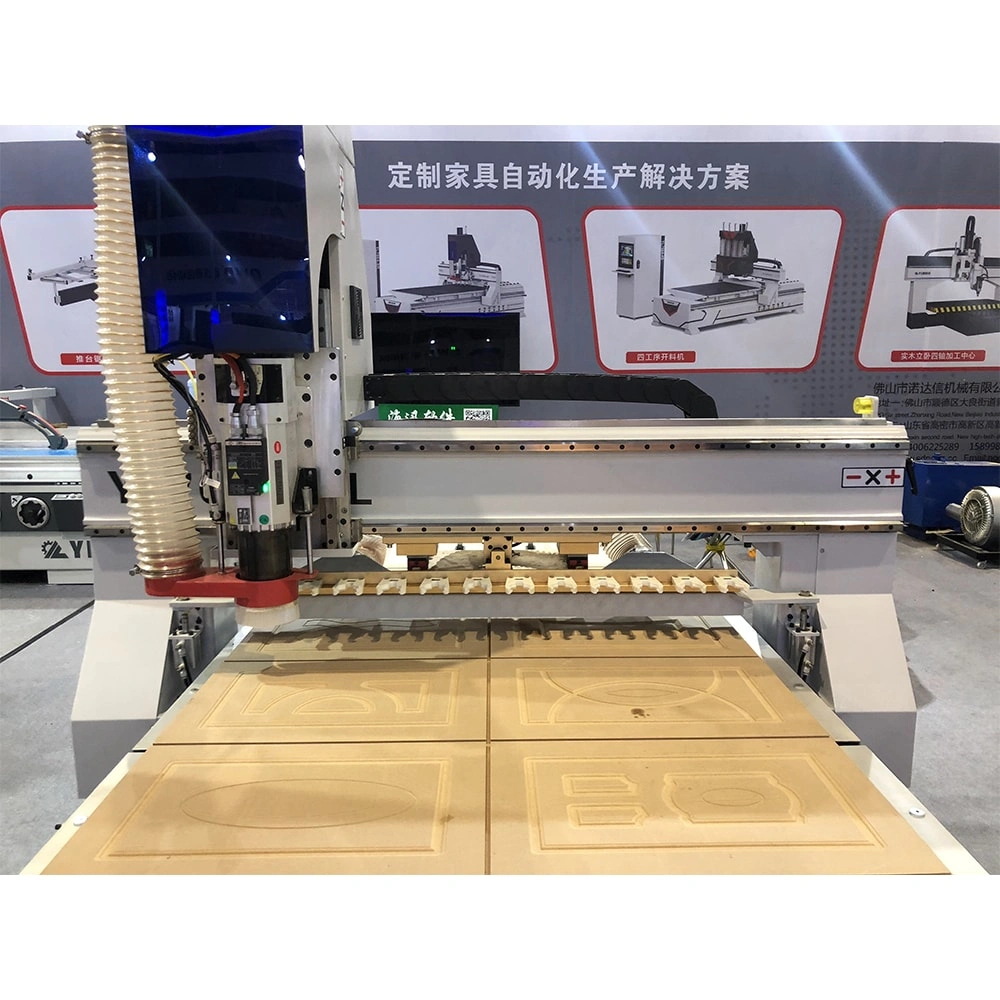

| Model | YL7084SR |

|---|---|

| Working Area(X、Y、Z axis) | 1300*2500*200mm |

| Machine Body | The bed lathe is made of thick square weld steel, which ensures a more stable working table. |

| Worktable | Vacuum worktable |

| Spindle motor | 9kw water-cooling Spindle |

| Driving motor | 1.3kw*4, Yaskawa Servo Motor |

| Vacuum pump motor | 5.5kw Air cooling |

| Blade store | 12 blade tools |

| Tool Diameter | φ3.175-φ12.7mm |

| Max. Speed | 75m/min |

| Max. Cutting Speed | 25m/min |

| Control System | RichAuto DSP |

| Support software | VCarve ,Artcam, Alphacam, Mastercam, Type3, UG, Caxa, JD Paint etc. |

| Guide way | Taiwan linear rail for X、Y、Z axis |

| Transmission | Helical gear rack for X Y-axis, Screw for Z-axis |

| Working precision | ±0.05mm |

| Feature | Vacuum worktable can do quick work pieces feed in and feed out. |

The CNC router is an automated machine equipped with a program control system.

The CNC router has high-precision automatic tool change spindle, fast tool change speed, no heat, can be installed with a variety of chucks.

The spindle of the CNC router is equipped with a high-power motor, and its rotational speed can reach 24,000 rpm per minute.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.