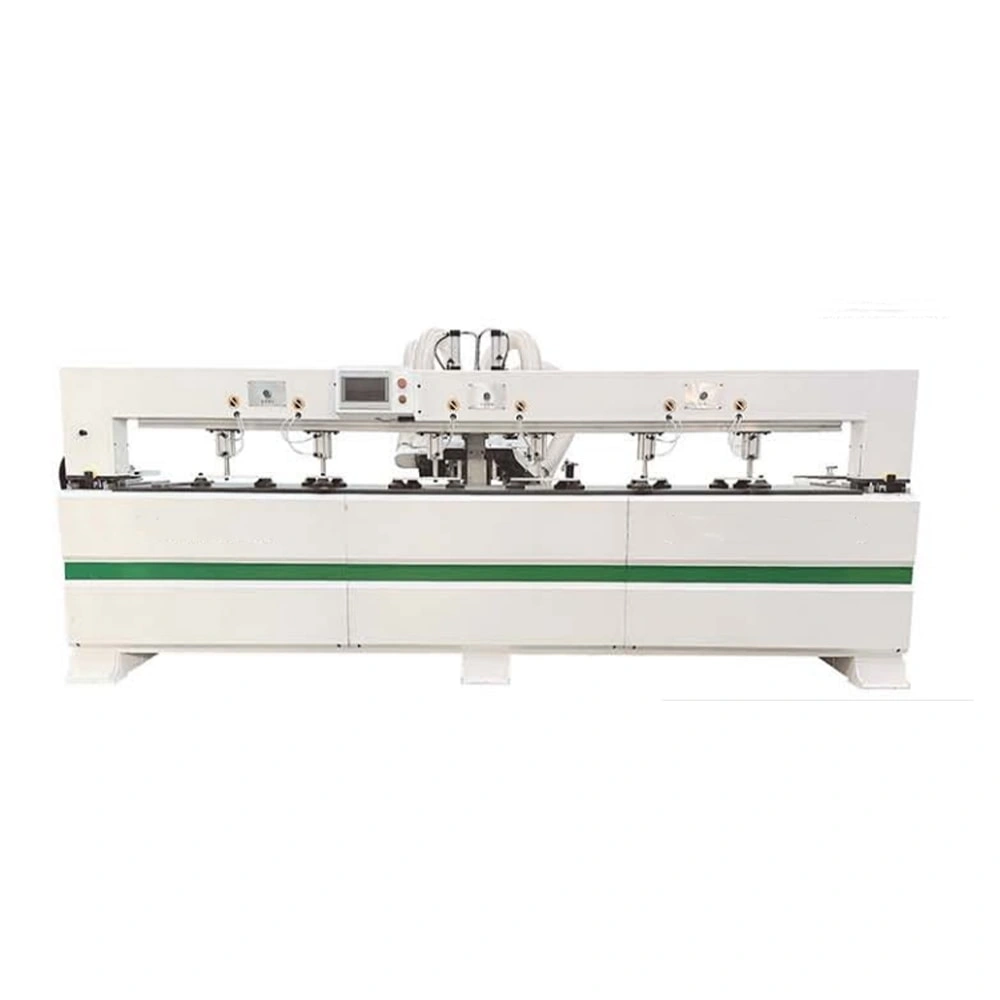

The CNC door lock & hinge milling is a key device in woodworking machinery used for slotting and drilling holes in wooden doors, window frames and furniture. The machine is generally composed of mechanical components such as a milling cutter, a milling slot, a worktable, and a motor. These components work closely together and coordinate with each other during operation.

| Model | MZHX4500 |

|---|---|

| Maximum work piece size | 2900*1300*50mm |

| Working length | 2800mm |

| T1 Upper hole spindle power | 3.5kw |

| T2 Upper milling spindle power | 3.5kw |

| T3 edge milling spindle power | 6kw |

| T4 edge trimming spindle power | 2.2kw |

The CNC door lock & hinge milling is mainly used for drilling door panels, lock holes and hinge holes. This machine combines all the elements required for furniture manufacturers to design and process custom cabinets, wardrobes, custom furniture and related products.

The CNC door lock & hinge milling is equipped with our independently developed operating system, which can accurately complete the data requirements input by the operator.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.