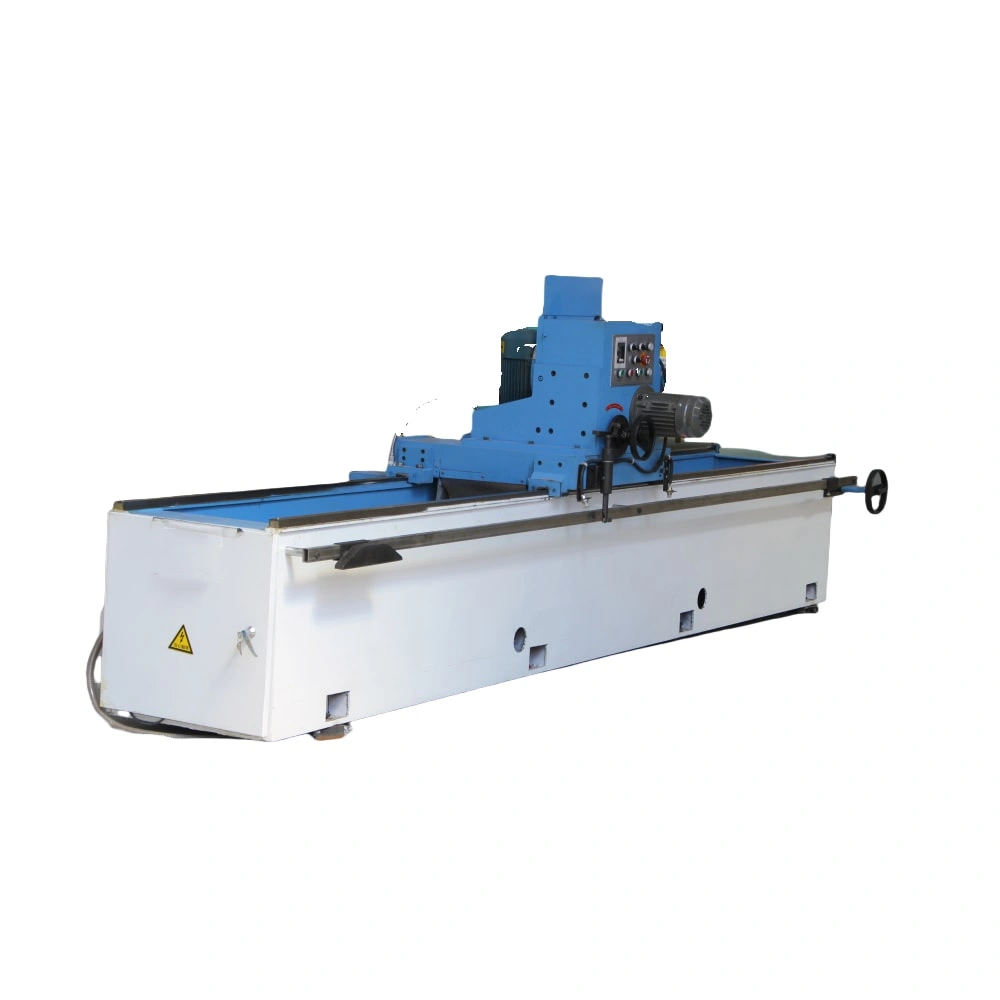

The chipper knife grinder body of the knife is made of welded steel plates and has undergone vibration aging treatment to enhance stability. The transmission system has been improved from a belt to a linear guide rail, with the grinding head swinging Angle exceeding 90 degrees. It is equipped with an automatic feed design to enhance efficiency.

| Model | MF2530 | MF2535 | MF2542 |

|---|---|---|---|

| Max grinding length | 3000mm | 3500mm | 4200mm |

| Working table size | 3000*180mm | 3500*180mm | 4200*180mm |

| Linear speed of grinding wheel | 15m/s | 15m/s | 15m/s |

| Sliding speed of grinding plate | 0-25m/min | 0-25m/min | 0-25m/min |

| Tilting range of the working table | ±90° | ±90° | ±90° |

| Tilting range of the grinding wheel | ±5° | ±5° | ±5° |

| Form for grinding wheel | Cup Style | Cup Style | Cup Style |

| Size of grinding wheel (mm) | Φ200x110x32 | Φ200x110x32 | Φ200x110x32 |

The chipper knife grinder is mainly grind all type of linear knives, like guillotine knives,slicer knife, peeling machine knife, cutting paper knife and Shearing Blades.

The worktable of chipper knife grinder is the electromagnetic chuck. It is very convenience to clamp knife. The worktable is easy to adjust the angle by worm gear. The width of the magnet is 180mm.

The chipper knife grinder has one, two or three grinding heads to choose .The moving up and down of the grinding head is depended on the ball screw.

The normal swing amplitude and frequency of the abrasive belt have their standard range. If not adjusted properly, the abrasive belt may operate in an abnormal state, causing it to deviate.

Check and adjust the swing amplitude and frequency of the abrasive belt to ensure they are within the normal range (usually the swing amplitude is 15-20mm and the swing frequency is 15-20 times per minute).

1.Regularly inspect and replace worn abrasive belts and contact rollers to ensure the sanding effect and processing accuracy.

2. Conduct a thorough cleaning of the equipment, especially regularly removing wood chips and dust from the surface of the sand belt and rollers.

The power source of the spray gun is controlled by the compressed air pressure valve. The pressure value directly affects the atomization effect of the spray. The working pressure range is 0.3-0.5Mpa.

Pour the cleaning agent into the feeding port of the paint spraying machine, start the paint spraying machine, and let the cleaning agent circulate in the pipeline to clean the paint and dirt inside the pipeline. This process can last for several minutes until the cleaning agent is discharged clearly.